Capabilities

Manufacturing Processes

As a distributor for many large OEMs, we are able to supply most standard, off the shelf parts and components. For custom designed products, we offer a wide range of manufacturing processes. Tapping into our global supply chain, we can often combine these manufacturing processes to offer a competitive cost while retaining an excellent level of quality. Batch produced lots can be stocked in one of our warehouses and released on your schedule, providing just in time shipments to help you run lean.

Fasteners

A variety of products focused on automotive specials and standards are warehoused in our 110,000-square-foot facility. Rivnuts, Screws, T-Bolts, Ball Studs, Clips, Ties, Sockets, and inserts are stocked and available for JIT delivery.

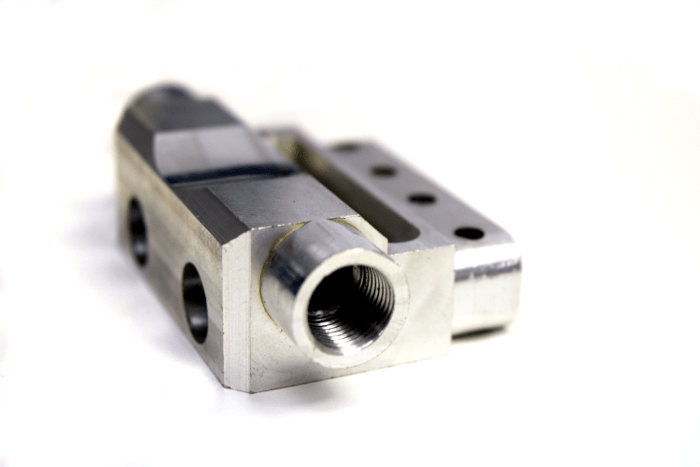

Precision Machining

Multi-axis machining centers give us flexibility to produce even the most complex parts efficiently and precisely.

Stamping

Variations include progression and transfer die stamped, deep drawn, and 4-slide parts. Short runs with laser cut and formed parts available.

Injection Molding

Injection molded rubber and plastic parts can be produced to your custom specifications. Overmolding of seals and gaskets, ultrasonic welding of inserts, and secondary assembly of components are available.

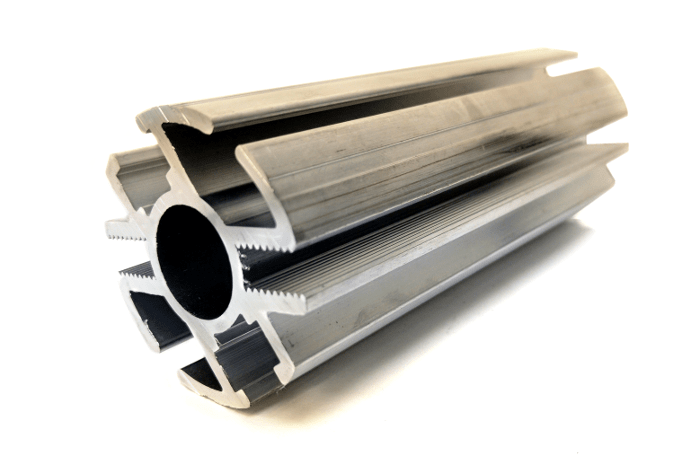

Extrusion

Carrdan supplies close tolerance aluminum and stainless extrusions for a variety of applications especially compression limiters and sleeves. Secondary operations on more complex designs can be done in-house to customize your application.

Casting & Forging

Zinc, aluminum, and steel die and cast parts are supplied with secondary machining processes available.